-

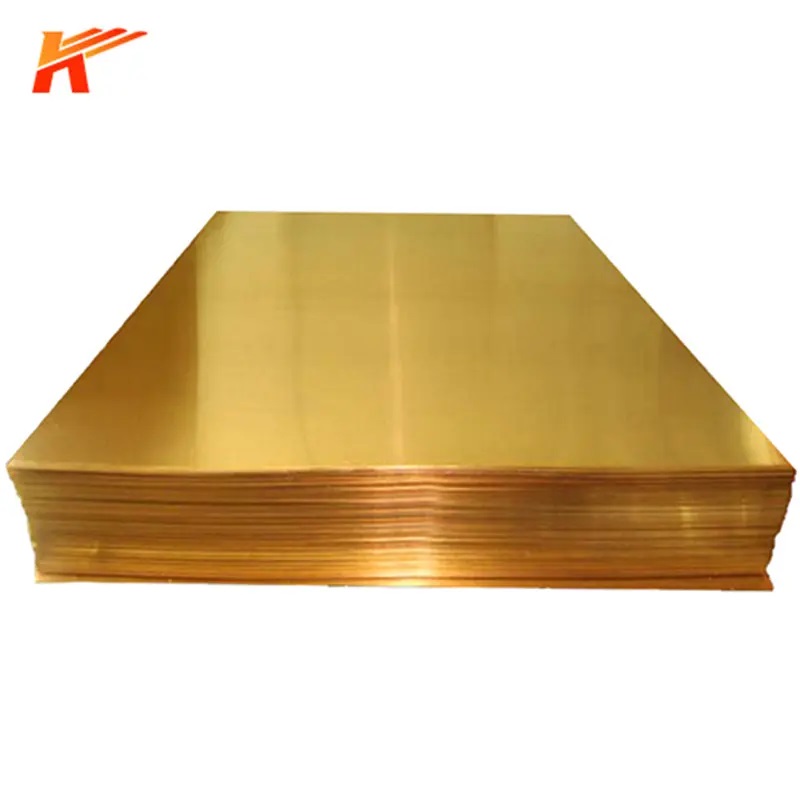

Application and chemical polishing treatment of brass sheet

Brass can be processed into brass sheet, brass wire, etc., is applied to every corner of life. First, it can be used in the HNA industry. Because brass plate whether in cold or hot state, have very good processing performance. So it is widely used in the parts processing of some Marine equipment ...Read more -

Brass sheet surface rust inhibitor treatment method

In order to make the surface of brass sheet more beautiful, cleaner, longer preservation time, usually carry on the surface rust inhibitor treatment, and there are many kinds of treatment, according to different states of different treatment: The first surface mechanical rust preventive treatment...Read more -

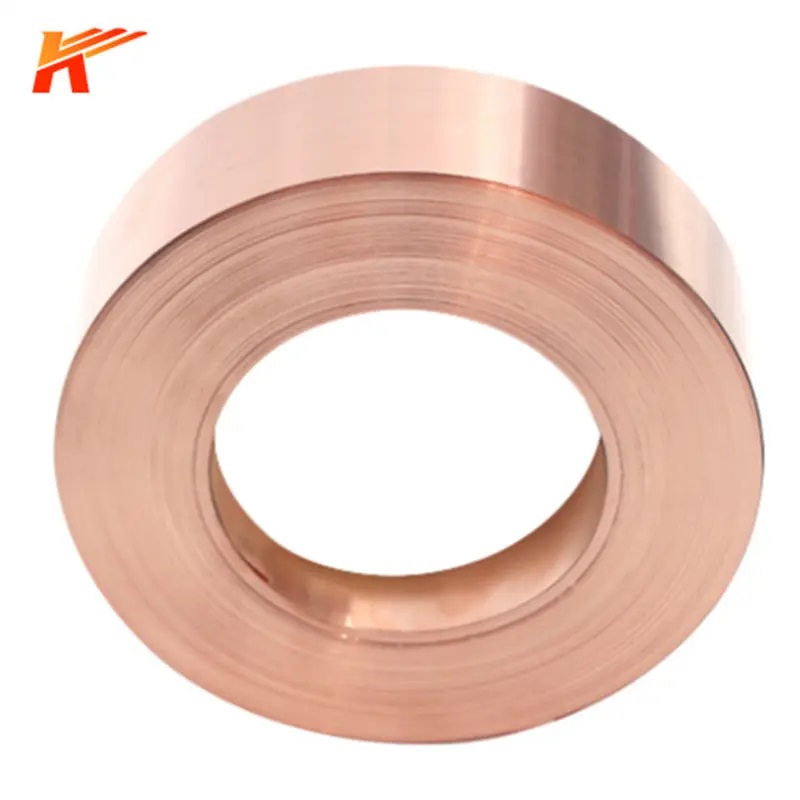

Difficulties in welding copper strips

Copper strip has good electrical and thermal conductivity, but there are still many difficult problems in the welding process. The thermal conductivity of red copper belt is much greater than that of steel. Welding heat is more likely to be lost, more likely to cause excessive internal stress, re...Read more -

The stability of brass sheet

In different buildings, different brass sheet products can be used, such as copper oxide plate. When used, it will form a uniform brown appearance and be more regular. Moreover, copper plates can also be used in the renovation of various old buildings, or some buildings with special requirements....Read more -

Processing technology and application of brass strip

Information technology is the precursor of high technology. The main trend of computer development is fast and stable data transmission, bandwidth and low power consumption. In the computer needs a large number of brass strip alloy for spring, contactor, switch and other elastic parts. A large nu...Read more -

Leaded brass tube processing requirements

First of all, leaded brass tube before processing can not have cracks, distortion, not round deformation, in the factory had made a defect mark, before processing must ensure the inner surface of clean, no water no oil. Secondly, the processing of the pipeline is processed in accordance with the ...Read more -

Reverse extrusion technology and selection principle of brass sheet

With the development of economy and science and technology, the quality requirements of extruded products are higher and higher, and some special requirements are put forward in some aspects, which promote the rapid development of brass sheet reverse extrusion technology. A new type of reverse ex...Read more -

Copper strip control surface quality measures

Copper strip high purity, fine tissue, oxygen content is very low. It has good electrical conductivity, thermal conductivity, corrosion resistance and machining properties, and can be welded and brazed. Measures to control the surface quality of red copper strip: first of all, we should strengthe...Read more -

Brass strip application and processing

Brass strip is a long conductor of rectangular or chamfered sections made of copper, used to carry current in circuits and connect electrical equipment. Because copper is better than aluminum in conducting electricity, brass strip has been widely used in electrical equipment, especially in power ...Read more -

Control method of surface quality of copper busbar

Surface quality control is the whole process of copper busbar production to product packaging control, is a fine management, careful operation of the system engineering, each process is the key to control product surface quality. The quality of billet surface is greatly affected by whether the co...Read more -

Brass sheet grinding process

Brass sheet polishing refers to the selection of a reflection of the effect, so that the surface of brass sheet is not smooth level shrink, make it more and more bright, leveling the surface of the solution. The key to polishing brass is to adopt two methods: mechanical chemical method and physic...Read more -

Influencing factors of copper busbar surface quality

Copper busbar products are mainly used in power, electronics, communication, heat dissipation, mold and other industries. With the development of national economy and the increasingly fierce market competition, users have higher and higher requirements on the surface quality of copper bus product...Read more