-

Precautions for processing tungsten copper rods

Tungsten copper rod is a two-phase structure pseudo-alloy mainly composed of tungsten and copper elements. It is a metal matrix composite material. After the composite materials are mixed, no chemical reaction occurs, and each maintains the original physical and mechanical properties. This materi...Read more -

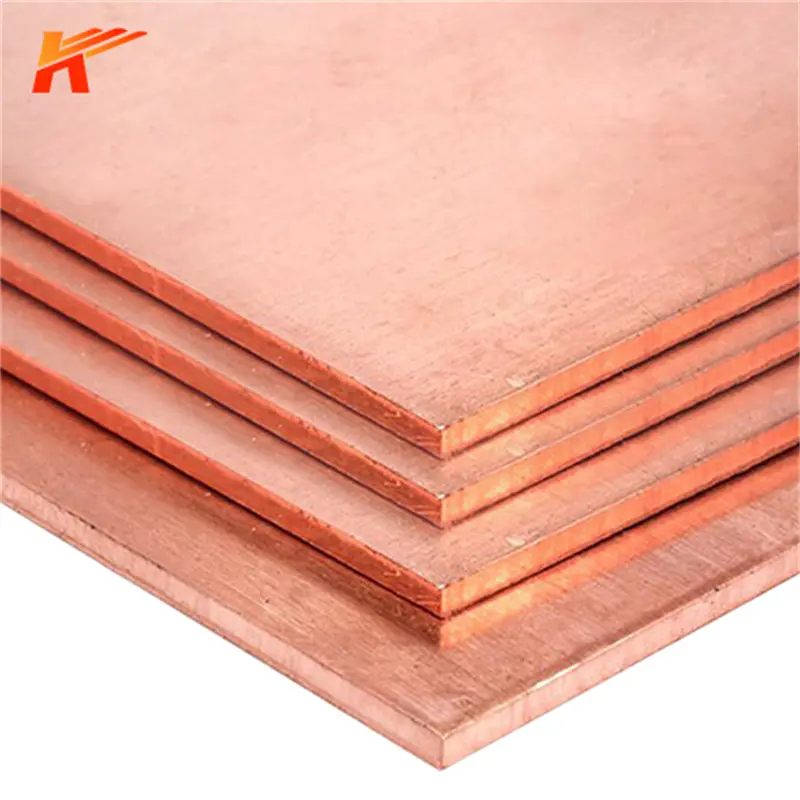

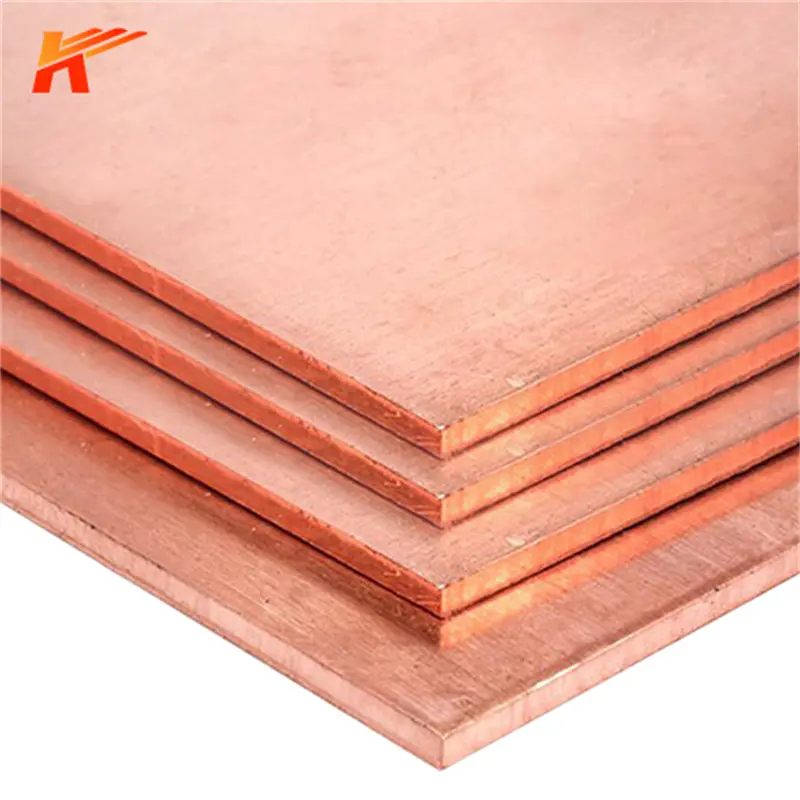

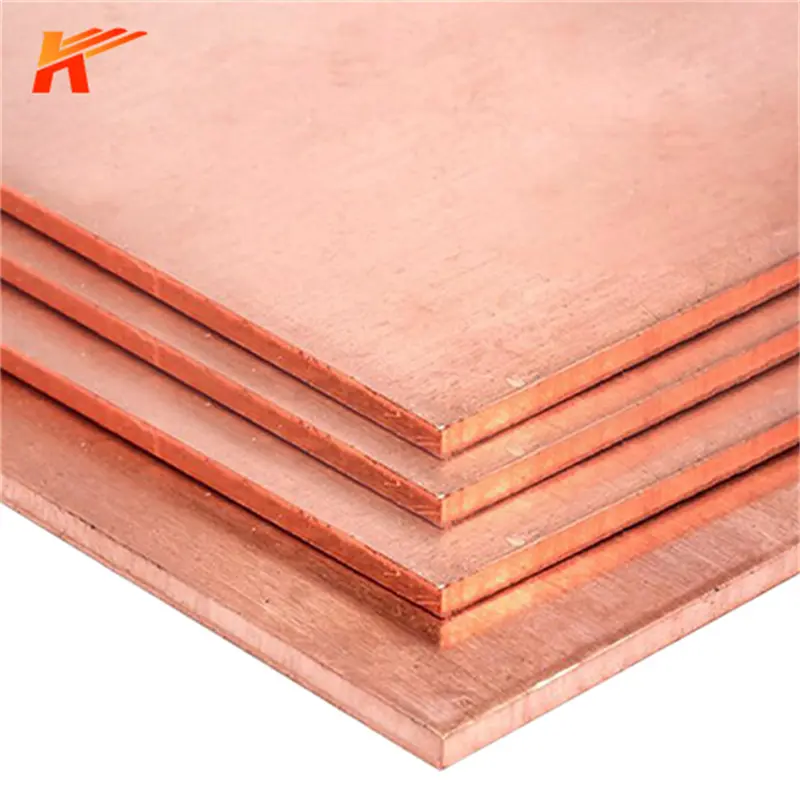

Analysis of the reason for peeling of copper sheet

When many people use the red copper sheet, they will find that the surface of the red copper sheet has peeling or dents. The red copper sheet has good electrical conductivity, thermal conductivity, corrosion resistance and processing performance, and can be welded and brazed. These peeling or pit...Read more -

What is the use of copper sheet?

Copper sheet have good mechanical properties, good thermal plasticity, acceptable plasticity, good processing, easy to weld and weld, excellent corrosion resistance, low price, so wide application. The mechanical properties of the copper sheet are also different from other metals, and the mechani...Read more -

How to distinguish copper wire?

Copper wire is a cable dominated by copper content, with a composition of 99.90%~99.97%, which is difficult to distinguish with the human eye. In the case of buying copper wire, generally choose a cable with a smooth surface, no series product lines and too soft. The conductivity of copper wire i...Read more -

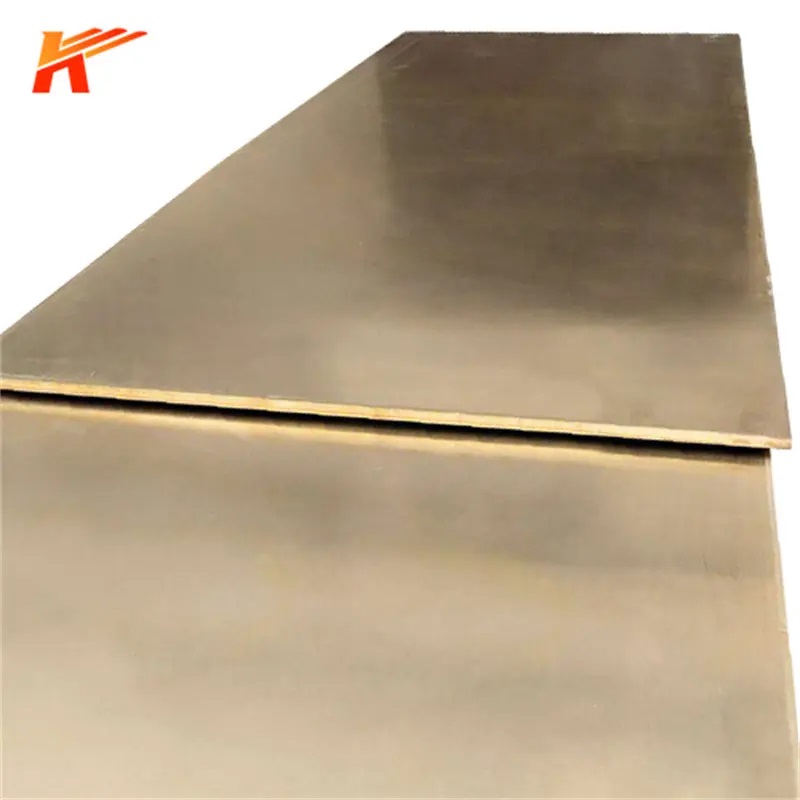

Copper sheet products production and processing and manufacturing

Copper sheet is a key type of copper processing material. It has high physical properties, excellent conductivity, heat transfer, excellent corrosion resistance, electroplating process, fibrous welding, and beautiful and beautiful metal texture and excellent quality The formation and processing c...Read more -

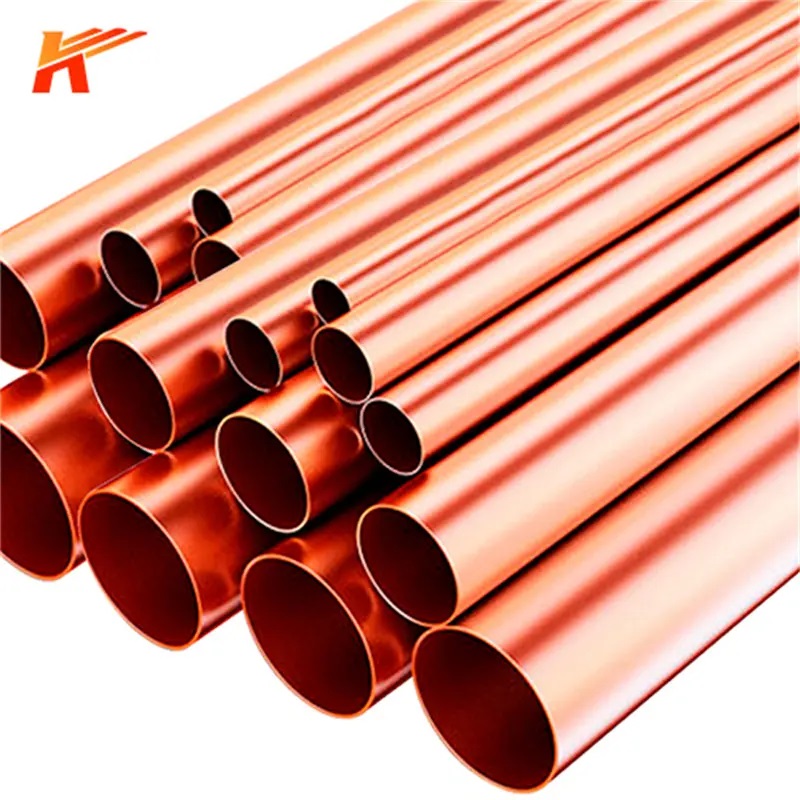

Brass Tube Features

Brass tubes are very common in daily life and are used in many fields. For example, the general cable protection and faucet hardware industries are using large amounts of brass tubing. This kind of pipe has good wear resistance and lubrication effect and can play a good role in many industries. F...Read more -

Treatment of chromium-zirconium copper after oxidation

Chromium-zirconium copper is mainly used for welding in the machinery manufacturing industry, where mechanical and physical properties can be obtained. When this material is used as a general resistance welding, the treatment methods of this material after oxidation are as follows. The vinegar so...Read more -

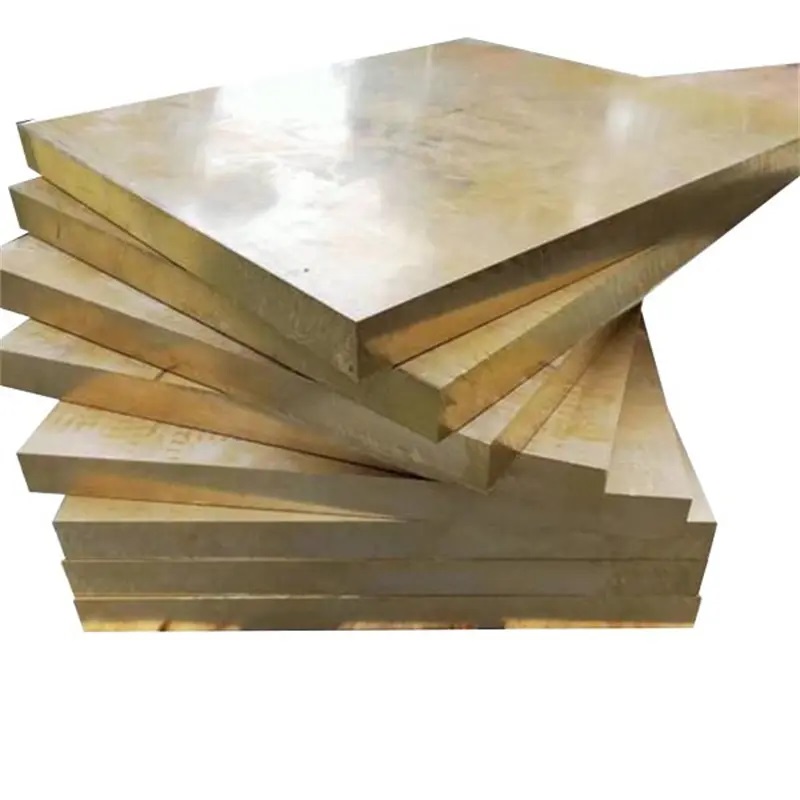

Selection of annealing process for tin bronze sheet

The phase transition temperature of tin bronze sheet from α→α+ ε is about 320 ℃, that is, the heating temperature is higher than 320 ℃, the structure is single-phase structure, until heated to 930 ℃ or so liquid phase structure, considering the use of equipment, the degree of oxidation of the wor...Read more -

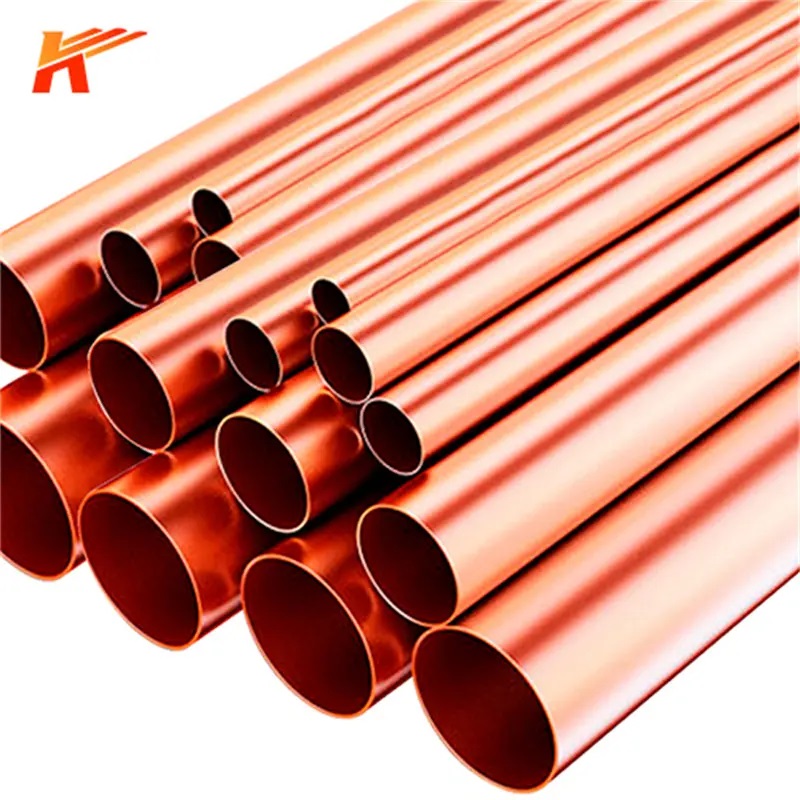

The advantage of copper tube

1. Safe and reliable: copper tube integrates the advantages of metal pipe and non-metal pipe. It is harder than plastic pipe, with the high strength of general metal (cold drawn copper pipe strength and the same wall thickness of steel pipe); It is more flexible than ordinary metals, good toughne...Read more -

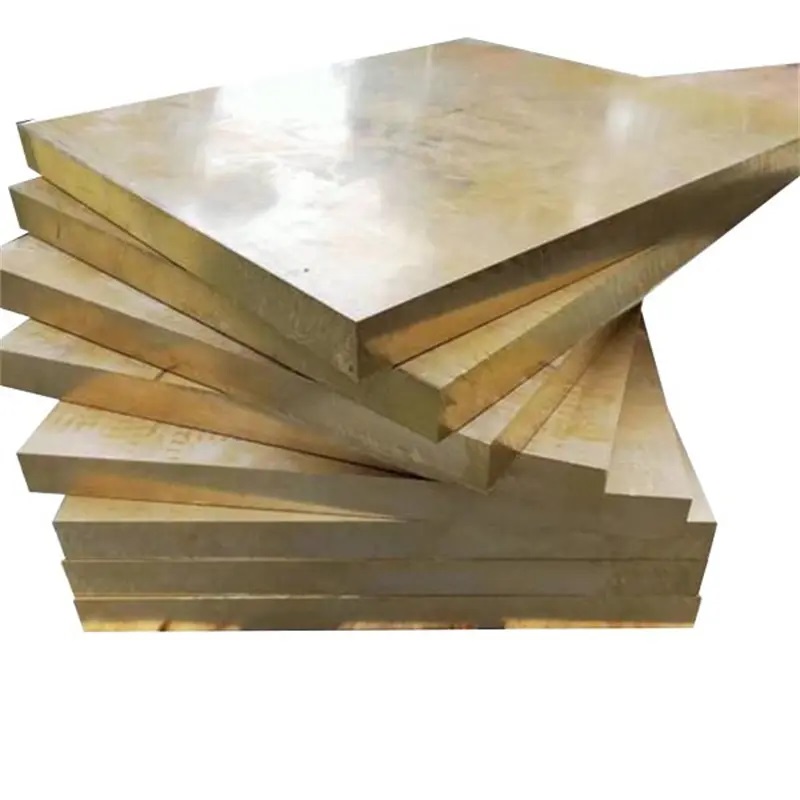

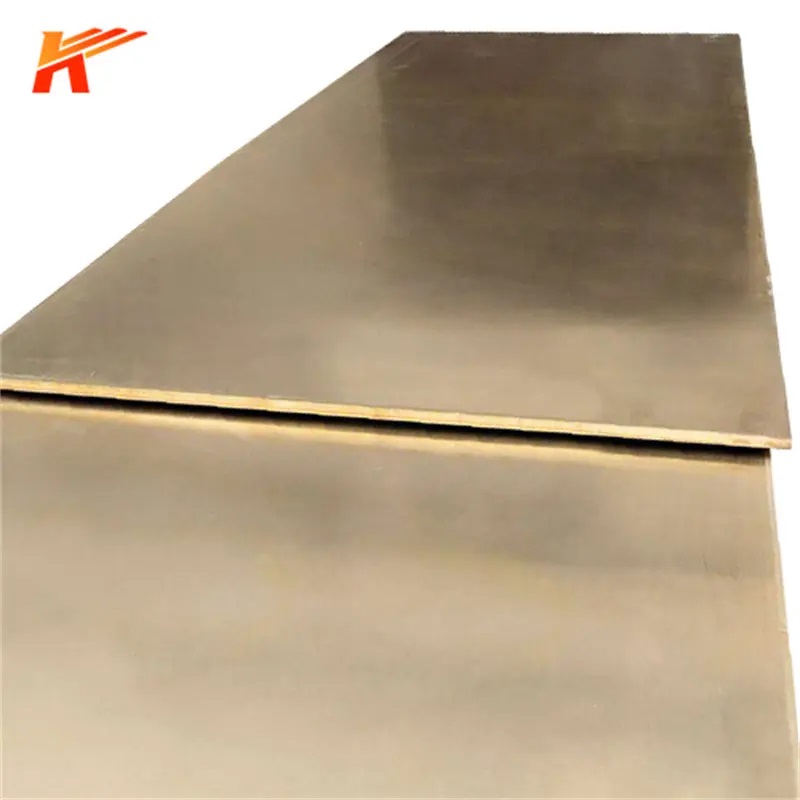

Carving brass sheet chemical polish use method and matters needing attention

Compared with mechanical polishing and electrochemical polishing, chemical polishing of brass does not need electricity and hanging tools. Therefore, it can polish the carved brass sheet with complex shape, and the production efficiency is high. The bright surface is obtained by chemical polishin...Read more -

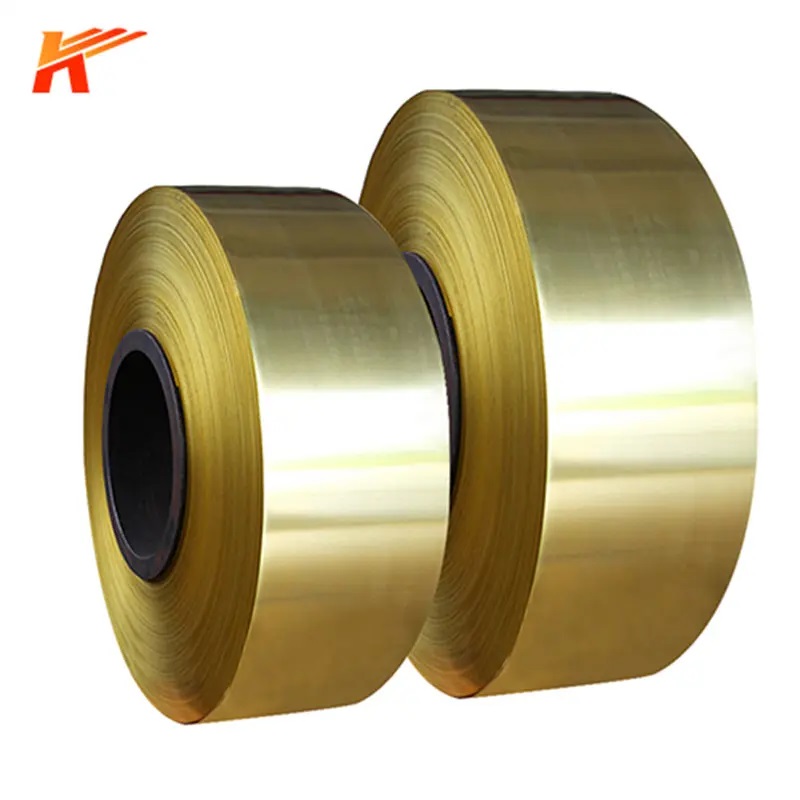

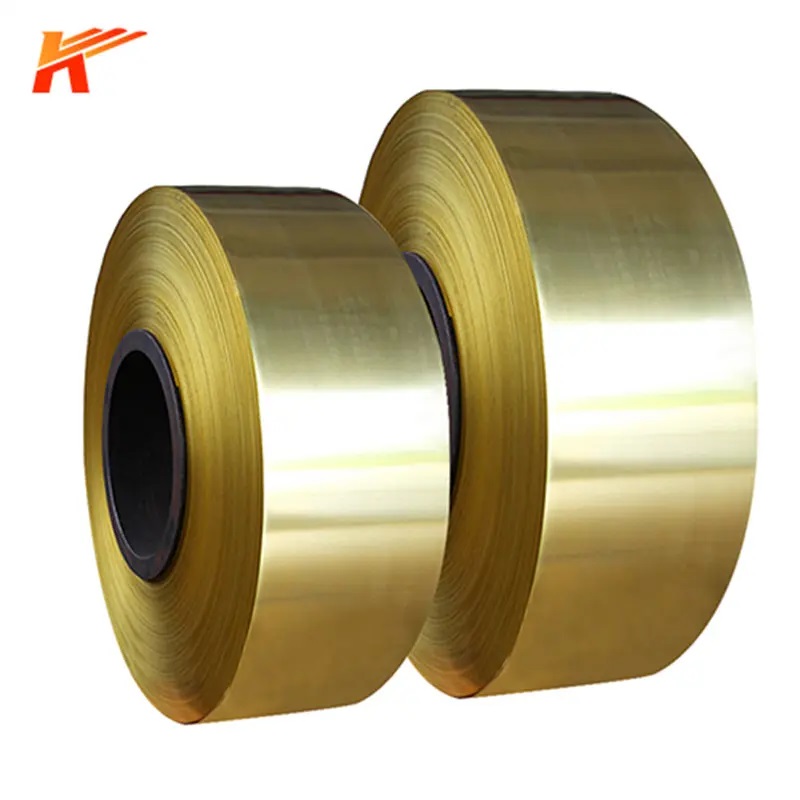

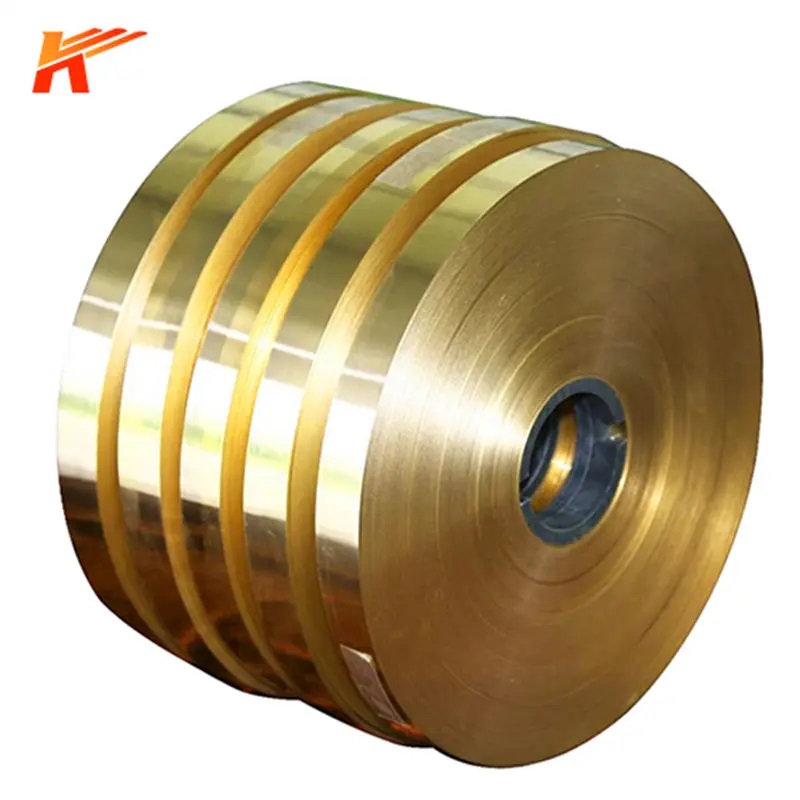

Milling surface quality of brass strip hot rolling process

The hot rolling process of brass strip is the first process of semi-continuous ingot heating, hot rolling and cold rolling, and it is also the key process of strip surface quality control. In the heating stage, the atmosphere in the furnace, the temperature, the heating time and the quality of co...Read more -

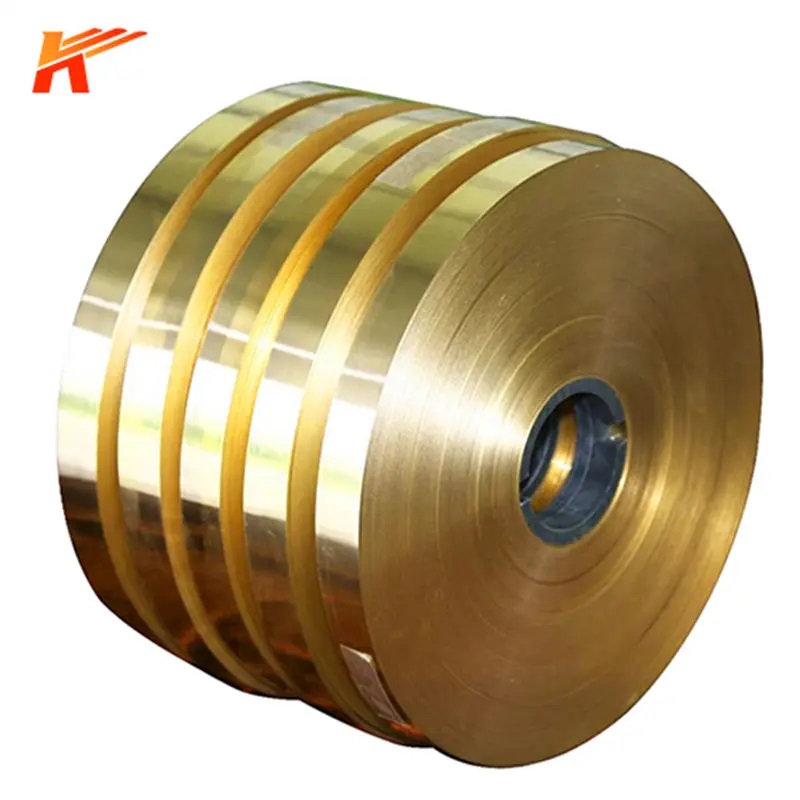

Laying requirements for brass strip

Brass strip in order to meet the requirements of high frequency protection, at the same time, but also in order to balance the voltage of the power grid, reduce the voltage difference, reduce the resistance of the power grid loop, we need to secondary equipment special grounding copper bar laying...Read more