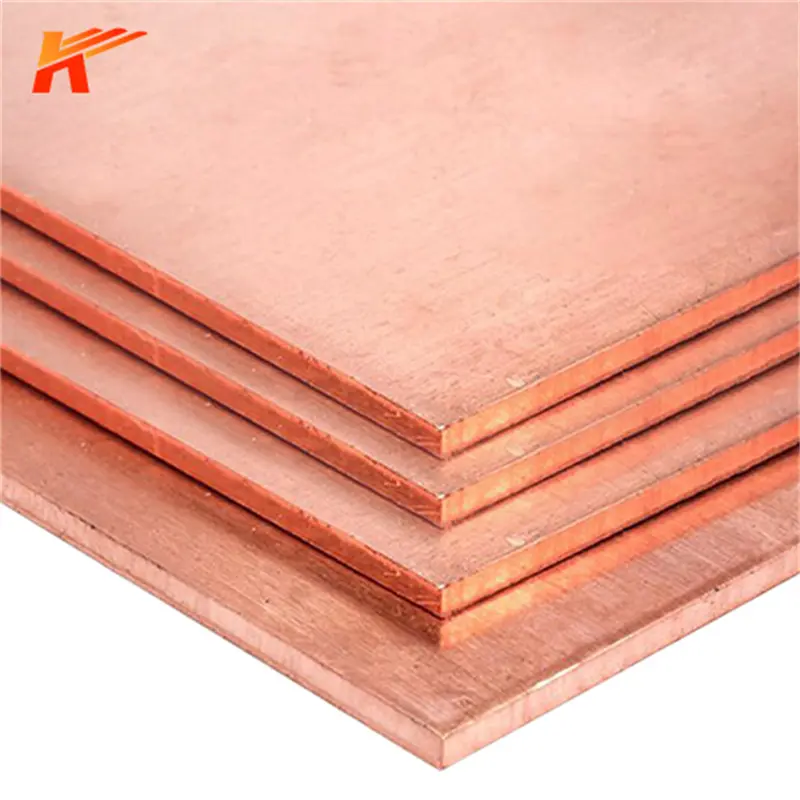

Copper sheet is a key type of copper processing material. It has high physical properties, excellent conductivity, heat transfer, excellent corrosion resistance, electroplating process, fibrous welding, and beautiful and beautiful metal texture and excellent quality The formation and processing characteristics of molding production, so it has been widely used in the power engineering industry with a variety of variable engineering, home appliance weapons and equipment.

is a key type of copper processing material. It has high physical properties, excellent conductivity, heat transfer, excellent corrosion resistance, electroplating process, fibrous welding, and beautiful and beautiful metal texture and excellent quality The formation and processing characteristics of molding production, so it has been widely used in the power engineering industry with a variety of variable engineering, home appliance weapons and equipment.

Here is how the copper plate is made:

1. Cold rolling-sawing method

The production process is: casting and heating-hot taver- (milling surface-opening-cold rolling-quenching-) Picky and passivation-cold rolling-sawing The school is straight-packaged-packaging-enter the warehouse. The characteristic is that the performance parameters of the copper plate can get good manipulation, but there are hair edges and drama crumbs, the edges are not arc, the surface layer is not smooth, the total width is large, and the high -precision regulations are not met. The product cost is higher.

2. Cold rolling-Lashen method

The production process is: casting and heating-hot taver-milling surface-cold rolling-cutting strips-quenching and passivation-La Shou-cast and rolling schools straight-packaging-packaged- Enter the warehouse. The characteristic is that all kinds of quality standards can obtain good manipulation and low -cost manufacturing, but the bronze plate cuts the edges and size tolerance cannot be manipulated.

3. Cold rolling method of aluminum profile

The production process is: iron mold red ingot-hot (warm) rolling-pickled passivation-rolled aluminum profile-quenching and passivation-refined aluminum profile-cast rolling school straight all fixed settings River-packaging-entering the warehouse. The characteristic is that the performance parameters of the copper plate can get a good manipulation.

4. Squeezing molding-Lashen method

The production process is: casting and heating-squeezing molding-Lashen-quenching-pickling passivation-La Sulin-casting and rolling schools directly-packaging-packaging. This processing process is added with quenching and pickling the detailed process to ensure that the copper plate is 180 ° bending characteristics, and the quality standards are manipulated. The process is simple, high efficiency, high production capacity, but the product cost is also very high.

5. Quoting (or level) Rolling steel-cold rolling-Lashen method

The production and production process of the copper board manufacturer is: upper (or level) rolling steel-cold rolling-quenching-pickling passivation-Lashen-Laoshen-Casting and rolling schools straight-packaging-entry library. The characteristic is that the process is simple and the product cost is low. However, performance parameters are not better than other ways. Specifications are restrained, low efficiency, and small production capacity.

Post time: Oct-21-2022