-

What is the main purpose of white copper? How can it be distinguished from silver?

We use a lot of metals in our lives, and there are metals in various products. White copper is a copper-based alloy with nickel as the main added element. It is silver-white and has metallic luster, so it is named cupronickel. Copper and nickel can be infinitely dissolved in each other, thus form...Read more -

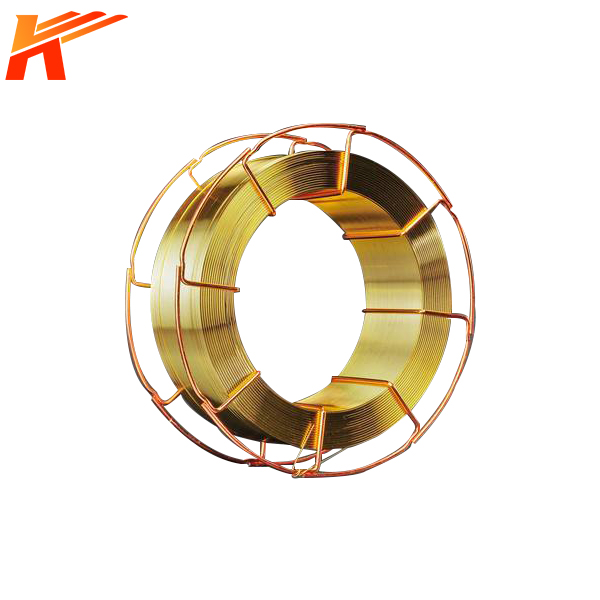

How to Melt Aluminum Brass

The aluminum brass series is more complicated, and some of the complex aluminum brass contain the third and fourth alloying elements such as manganese, nickel, silicon, cobalt and arsenic. HAl66-6-3-2 and HAl61-4-3-1, which have more alloying elements, are alloys composed of six elements, and som...Read more -

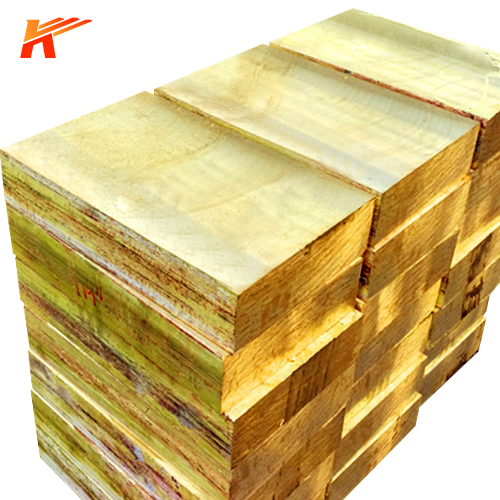

How to Smelt Simple Brass

Raw material selection The raw material taste should improve with the taste of brass varieties. When smelting non-essential brass, if the quality of the charge is reliable, sometimes the use of old material can reach 100%. However, in order to ensure the quality of the melt and reduce the burning...Read more -

Changes in properties of chromium zirconium copper after heat treatment

After solution aging treatment, fine black precipitates are densely distributed at the grain boundaries of chromium zirconium copper, and many small black precipitates are also distributed in the grain, with a size of about a few microns. As the temperature decreases, the curve approaches the cop...Read more -

What is the difference in performance between tin bronze and beryllium bronze?

Tin bronze is actually a metal material with tin as the main alloying element, and its tin content is generally between 3-14%. This material is mainly used to make elastic components and wear-resistant parts, deformed tin bronze The content of tin does not exceed 8%, and sometimes lead, phosphoru...Read more -

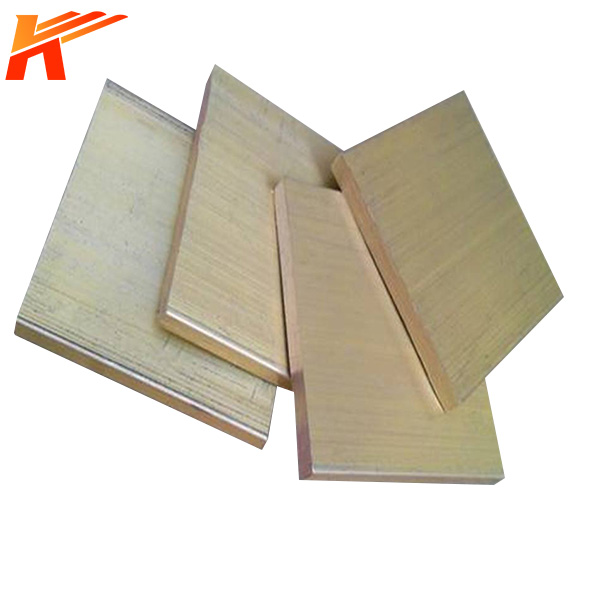

Hardness of brass

Ordinary Brass It is an alloy of copper and zinc. When the zinc content is less than 39%, zinc can dissolve in copper to form single-phase a, called single-phase brass, which has good plasticity and is suitable for hot and cold press processing. When the zinc content is more than 39%, there is a ...Read more -

Heat Treatment Process of Tin Bronze Contacts

Some switchgear contact parts are made of tin bronze material, which requires good elasticity, wear resistance, anti-magnetic and corrosion resistance. Due to the complex shape of the part, in the process of stamping and bending, in order to make the workpiece have sufficient toughness while main...Read more -

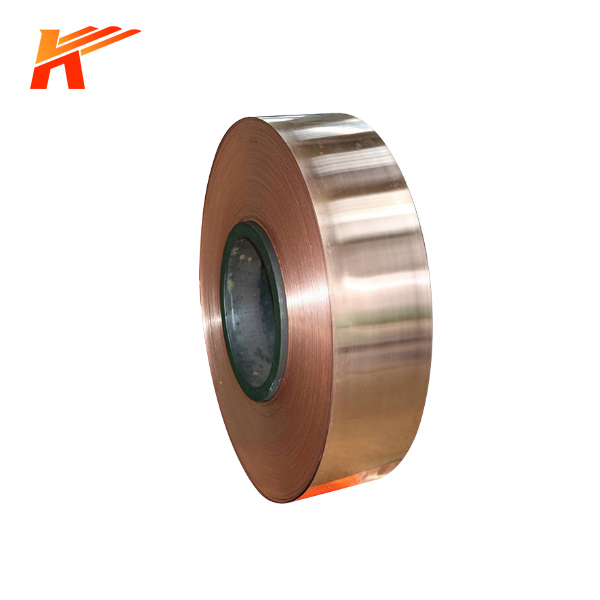

The use of copper in production and life

conductivity of copper One of the most important properties of lead-free copper is that it has excellent electrical conductivity, with a conductivity of 58m/(Ω.mm square). This property makes copper widely used in the electronics, electrical, telecommunications and electronics industries. This hi...Read more -

Copper alloy corrosion

Copper alloys have excellent resistance to atmospheric and seawater corrosion, such as silicon bronze, aluminum bronze and so on. In general media, it is dominated by uniform corrosion. There is strong stress corrosion susceptibility in the solution in the presence of ammonia, and there are also ...Read more -

Application of Copper in Light Industry

Application of Copper in Paper Industry In the current information-changing society, paper consumption is huge. The paper looks simple on the surface, but the papermaking process is very complex, requiring many steps and the application of many machines, including coolers, evaporators, beaters, p...Read more -

What are the factors that cause copper alloy corrosion

Copper alloy corrosion atmospheric corrosion The atmospheric corrosion of metal materials mainly depends on the water vapor in the atmosphere and the water film on the surface of the material. The relative humidity of the atmosphere when the corrosion rate of the metal atmosphere begins to increa...Read more -

Applications and uses of lead-free copper

Applications and uses of lead-free copper 1. It is suitable for all kinds of cold heading, bending and riveting parts, electronic and telecommunication connectors, connectors and other parts with ecological environmental protection and health and safety requirements. 2. It is suitable for automat...Read more