-

Precautions for processing tungsten copper sheet

Tungsten-copper sheet, a metal material, is a two-phase structure pseudo-alloy mainly composed of tungsten and copper elements. It is a metal matrix composite material. Due to the great difference in physical properties between metal tungsten and tungsten, it cannot be produced by the melting and...Read more -

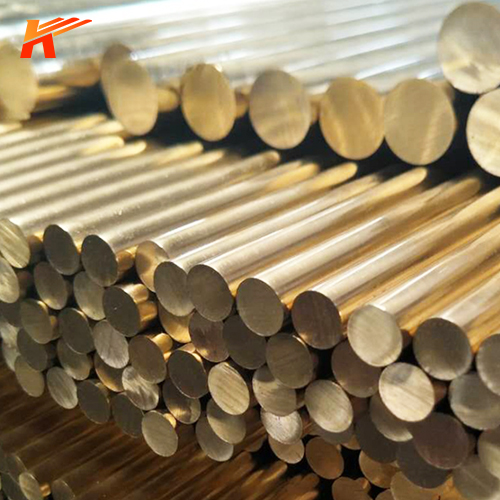

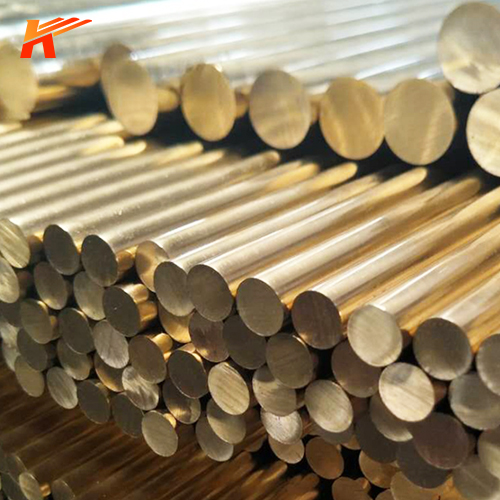

Principle of copper rod forming process

1. All elements reduce the electrical conductivity and thermal conductivity of the copper rod without exception. All elements are dissolved in the copper rod, causing the lattice distortion of the copper rod, causing wave scattering when the free electrons flow directionally, making the resistivi...Read more -

Copper rod forming process and process

Before introducing the copper rod forming process and process, what are the metal forming processes? 1. Metal solidification and forming is customarily called casting. Casting is a process in which molten metal is poured, injected or inhaled into a mold cavity, and after it solidifies, a casting ...Read more -

Precautions in the extrusion process of brass rods

During the extrusion process of the brass rod, the ingot is subjected to three-way compressive stress in the extrusion cylinder and can withstand a large amount of deformation; when extruding, it should be based on the characteristics of the alloy, the specifications and technical requirements of...Read more -

Common Classification of Copper Alloys

Classification of Copper Alloys: By Alloy System 1. Unalloyed copper: Unalloyed copper includes high-purity copper, tough copper, deoxidized copper, oxygen-free copper, etc. In general, pure copper is also called red copper. 2. Other copper alloys belong to alloy copper. In my country and Russia,...Read more -

Characteristics and Application of Chromium Zirconium Copper

Chromium zirconium copper (CuCrZr) chemical composition (mass fraction) % (Cr: 0.1-0.8, Zr: 0.3-0.6) hardness (HRB78-83) conductivity 43ms/m softening temperature 550 ℃ Chromium zirconium copper features high strength And hardness, electrical conductivity and thermal conductivity, wear resistance...Read more -

C17000 Beryllium Copper Composition Physical Properties Main Uses

Introduction of C17000 Beryllium copper: C17000 beryllium copper has good cold drawing properties and excellent heat treatment performance. C17000 beryllium copper key as pulse damper, diaphragm, metal bellows, torsion spring. Element: Copper + required element Cu: ≥99.50 Nickel+Cobalt Ni+Co: ≤0....Read more -

Effect of Cerium on Properties of Tin Phosphor Bronze Alloy

Experiments have proved the influence of cerium on the microstructure of the tin-phosphor bronze QSn7-0.2 alloy that has been cast, homogenized and recrystallized. The mesh becomes finer, and the grain structure is obviously refined after deformation annealing. Adding a small amount of rare earth...Read more -

Introduction to the use of phosphor bronze plate

Uses of Phosphor Bronze Plates: bronze (phosphor bronze) (tin bronze) (phosphor tin bronze) is added from bronze with degassing agent phosphorus P content of 0.03~0.35%, tin content of 5~8%. And other trace elements like iron Fe , Zinc Zn and other compositions have good ductility and fatigue res...Read more -

What is the density of tin bronze?

Tin bronze density specific gravity ρ (8.82). Bronze can be divided into two categories: tin bronze and special bronze (ie Wuxi bronze). For casting products, add the word “Z” before the code, such as: Qal7 means that the aluminum content is 5%, and the rest is copper. Copper casting ...Read more -

The difference between lead tin bronze and tin bronze

Differences between lead-tin bronze and tin bronze Phosphor bronze. Tin phosphor bronze has higher corrosion resistance, wear resistance, no sparks when punching out. It is used for bearings at medium speeds and heavy loads, and the working temperature is 250 ° C. It has self-aligning and no defl...Read more -

The difference between aluminum bronze and beryllium copper

Beryllium copper, also known as beryllium bronze, is the “king of ductility” in alloy copper. After solid solution aging quenching and tempering treatment, a commodity high toughness forged beryllium bronze aluminum alloy with high toughness and high electrical conductivity can be obt...Read more