-

What are the ways to identify pure copper

1. Check the hardness: the higher the fineness of copper jewelry, the softer the texture and the whiter and smoother the surface. Copper alloy manufacturers take copper bracelets of about 60 grams as an example. If they are pulled open by hand, there is no elasticity, and their fineness is about ...Read more -

Application of beryllium copper alloy in automobile mould

The conclusion of the application of beryllium copper alloy in automobile die The stamping operation of automobile panel is one of the four major processes of vehicle manufacturing, and it is the primary link in body manufacturing. The quality level of stamping parts lays the foundation for the q...Read more -

Why do many plastic mold manufacturers choose beryllium copper?

Nowadays, more and more plastic mold manufacturers have begun to use beryllium copper mold materials. Among many metal materials, what makes beryllium copper more and more popular? What kind of characteristics make it stand out? Maybe many people don’t know what kind of metal beryllium copp...Read more -

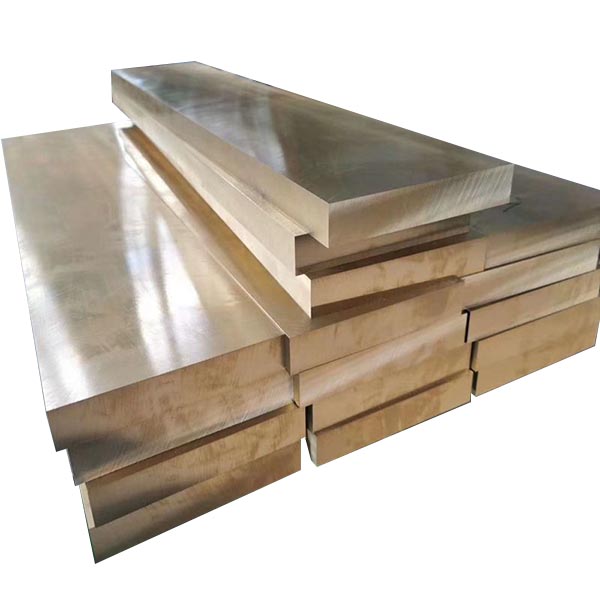

What are the material selection methods for brass copper alloys?

Brass has good processing performance and is often used for cutting into various accessories. Among them, the most used brass material in cutting is Pb-containing brass. Lead-containing brass has excellent chemical, physical, mechanical and free cutting properties, and is the most widely used cop...Read more -

Chemical Properties of Lead-Free Copper

Lead-free copper has a high positive potential, cannot replace hydrogen in water, and has excellent corrosion resistance in the atmosphere, pure water, seawater, non-oxidizing acid, alkali, salt solution, organic acid medium and soil, but copper is easily oxidized , when the temperature is greate...Read more -

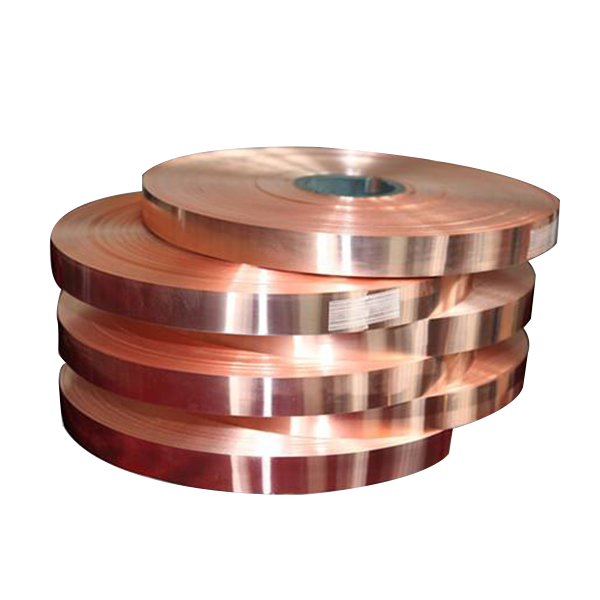

Selection of Annealing Process for Tin Bronze Sheet

1. Heating temperature, holding time and cooling method: The phase transition temperature of the tin bronze plate from α→α+ε is about 320 ℃, that is, the heating temperature is higher than 320 ℃, and its structure is a single-phase structure, until it is heated to 930 The liquid phase structure a...Read more -

How to prevent defects from tin bronze plate

The defects of the tin bronze plate are mainly manifested in the unreasonable structural design of the casting, sharp corners, and the wall thickness of the casting is too different; the sand mold (core) has poor retreat; the mold is partially overheated; the pouring temperature is too high; Prem...Read more -

Welding between tin bronze plate and steel

Tin bronze plate is very resistant to corrosion in the atmosphere, sea water, fresh water and steam, and is widely used in steam boilers and marine ship parts. The solidification range of the tin bronze plate is large, and the dendrite segregation is serious; it is not easy to form concentrated s...Read more -

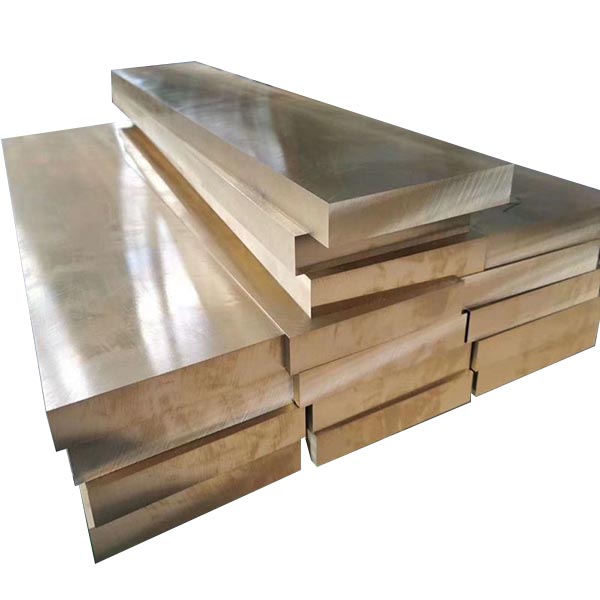

Performance Advantages of Cast Copper Alloys

Copper alloy is an alloy composed of pure copper as the matrix and one or several other elements added. According to the material formation method, it can be divided into cast copper alloy and deformed copper alloy. Most cast copper alloys cannot be press worked, such as cast beryllium bronze and...Read more -

Extensive use of aluminum bronze in life

Aluminum bronze won’t produce sparks under impact, and may be wont to make non-sparking tool materials. it’s excellent thermal conductivity and stable stiffness. it’s the benefits of scratching the workpiece so on, and has become a replacement sort of mold material. it’s p...Read more -

The casting process of tin bronze plate

Tin bronze plate casting is bronze wont to produce castings. Bronze castings are widely employed in machinery manufacturing, ships, automobiles, construction and other industrial sectors, forming cast bronze series in heavy non-ferrous metal materials. Commonly used cast bronzes are tin bronze pl...Read more -

Application scope of tungsten copper plate

Tungsten copper plate combines the advantages of metal tungsten and copper. Among them, tungsten has a high melting point and high density. The melting point of tungsten is 3410 degrees Celsius, and the melting point of copper is 1083 degrees Celsius. Copper has excellent electrical and thermal c...Read more