-

Smelting properties of tin bronze

The most harmful impurities in tin bronze are aluminum, silicon and magnesium. When their content exceeds 0.005%, the resulting SiO2, MgO and Al2O3 oxide inclusions will contaminate the melt and reduce the performance of some aspects of the alloy. When smelting tin bronze, since the boiling point...Read more -

Different grades of tin bronze

Tin bronze has been widely used in various industrial sectors for a long time. However, the grades of tin bronze are different, and their performance and uses are also different. QSn4-3: It has good elasticity, wear resistance and diamagnetism, and has good processing performance in hot and cold ...Read more -

Copper alloy composition detection and characteristics

Copper alloy composition detection and characteristics? What are the detection methods of copper alloy composition? Copper alloy composition detection steps? What are the characteristics of copper alloy composition detection? The copper alloy composition we are talking about here mainly refers to...Read more -

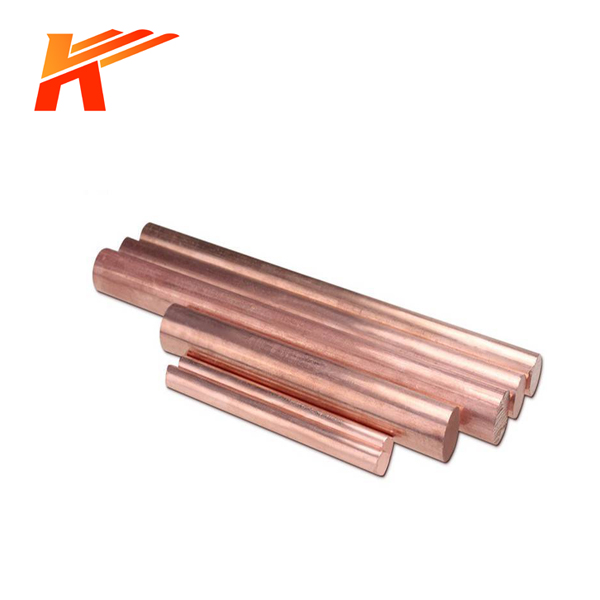

How to identify the type of copper alloy

How to identify the type of copper alloy? White copper, brass, red copper (also known as “red copper”), and bronze (blue-gray or gray-yellow) are distinguished by color. Among them, white copper and brass are very easy to distinguish; red copper is pure copper (impurities <1%) and ...Read more -

The production process of tungsten copper alloy

The production process of tungsten copper alloy: The technical process of preparing tungsten-copper alloy by powder metallurgy method is used for mixing, limiting, forming, sintering, melting, infiltration and cold production of powdered ingredients. Tungsten-copper or molybdenum-copper mixed pow...Read more -

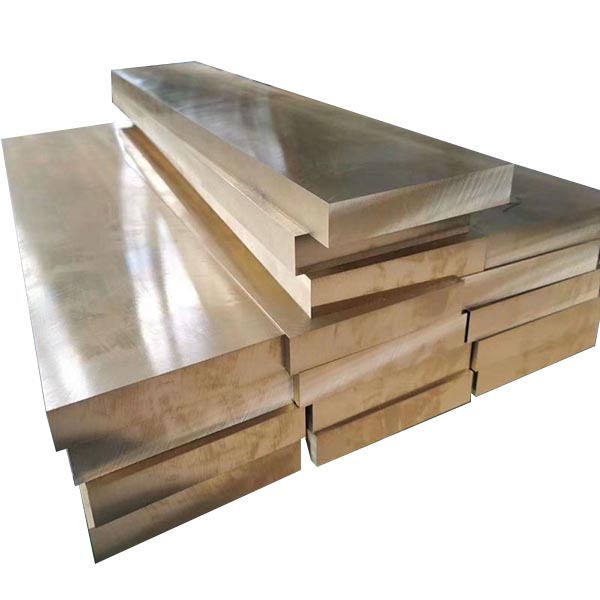

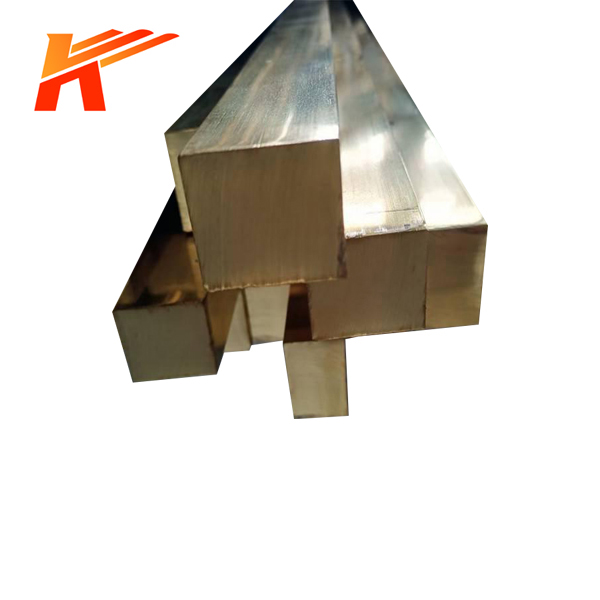

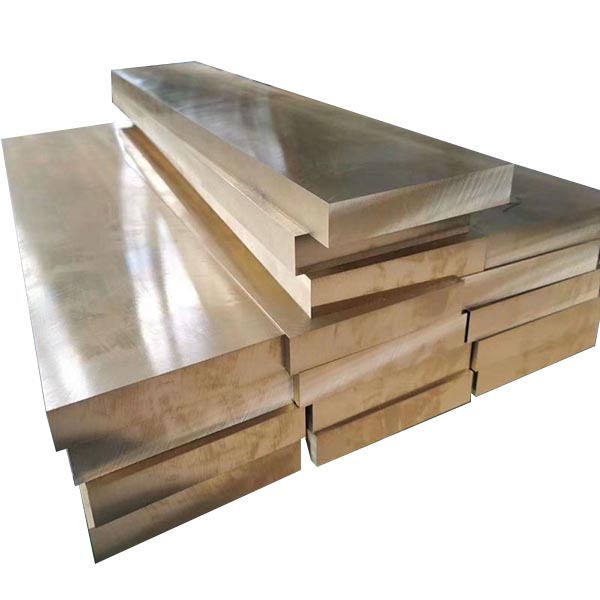

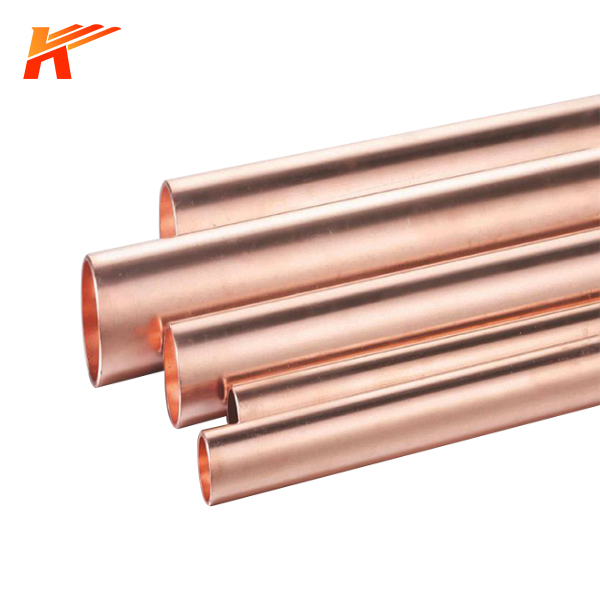

Can aluminum bronze be replaced by tin bronze plate

Can aluminum bronze be replaced by tin bronze plate? As an elastic alloy, tin bronze plate refers to a copper-tin alloy containing Sn≤6.5%, usually still containing P, Zn and other alloy elements. If it also contains P, it is called phosphor-tin bronze, which has high elastic limit, elastic modul...Read more -

Processing method of copper and copper alloy sheet, strip and foil

Processing method of copper and copper alloy sheet, strip and foil: Rolling is the basic method for the production of copper and copper alloy strips. Rolling is in a gap between two rolls that have a certain pressure on each other and rotate in opposite directions to roll out the product, and the...Read more -

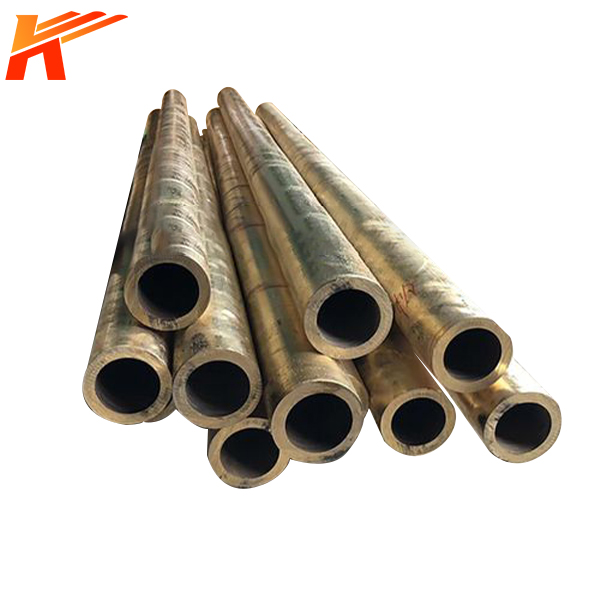

What are the casting methods for lead-free copper sleeves?

Sand casting is the most common method for copper gaskets used in sand casting production, which has the advantages of wide adaptability and relatively simple production preparation. However, the dimensional accuracy, surface quality, and internal quality of castings produced by this method are f...Read more -

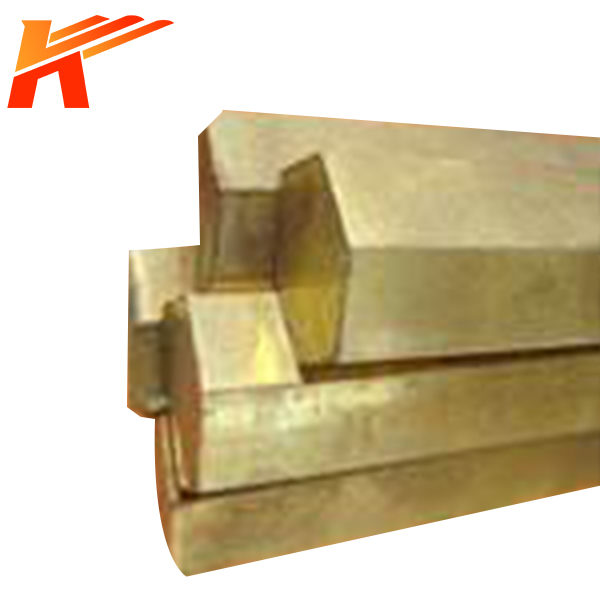

Application of various grades of tin bronze

QSn4-3 tin bronze: tin bronze containing zinc. It has high wear resistance and elasticity, good anti-magnetic properties, can withstand hot or cold pressure processing well; in hard state, good machinability, easy welding and brazing, corrosion resistance in atmosphere, fresh water and sea water ...Read more -

Welding properties of various copper alloys

Welding properties of various copper alloys: 1. The thermal conductivity of red copper is high. The thermal conductivity of red copper at room temperature is about 8 times larger than that of carbon steel. It is difficult to locally heat the copper weldment to the melting temperature. Therefore, ...Read more -

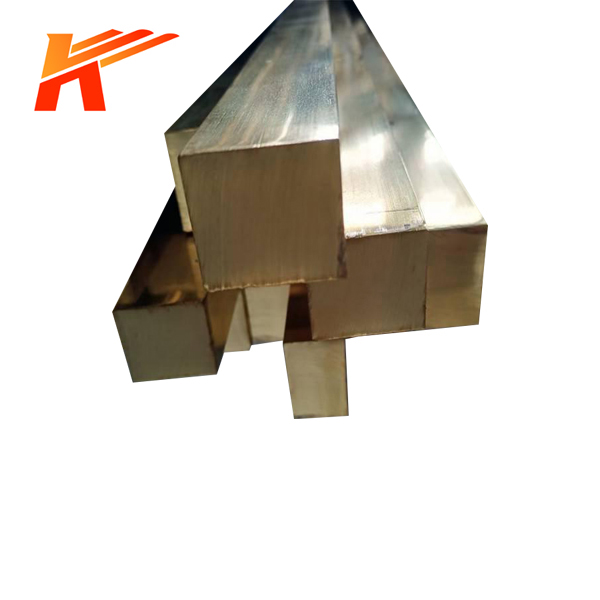

Use of special brass

In order to meet the requirements of making structural parts, it is widely used in the industry to add alloying elements to copper to make copper alloys with enhanced properties. Brass is a copper alloy with zinc as the main alloying element, which has good mechanical properties and is easy to pr...Read more -

Performance Advantages of Cast Copper Alloys

1. Process characteristics: Most copper alloys have large shrinkage, that the solidification sequence should be controlled during casting to stop the formation of shrinkage cavities. Tin bronze is well oxidized within the liquid state, that the flow shouldn’t be interrupted during pouring. ...Read more