Company News

-

How to Smelt Simple Brass

Raw material selection The raw material taste should improve with the taste of brass varieties. When smelting non-essential brass, if the quality of the charge is reliable, sometimes the use of old material can reach 100%. However, in order to ensure the quality of the melt and reduce the burning...Read more -

What is the difference in performance between tin bronze and beryllium bronze?

Tin bronze is actually a metal material with tin as the main alloying element, and its tin content is generally between 3-14%. This material is mainly used to make elastic components and wear-resistant parts, deformed tin bronze The content of tin does not exceed 8%, and sometimes lead, phosphoru...Read more -

Heat Treatment Process of Tin Bronze Contacts

Some switchgear contact parts are made of tin bronze material, which requires good elasticity, wear resistance, anti-magnetic and corrosion resistance. Due to the complex shape of the part, in the process of stamping and bending, in order to make the workpiece have sufficient toughness while main...Read more -

Copper alloy corrosion

Copper alloys have excellent resistance to atmospheric and seawater corrosion, such as silicon bronze, aluminum bronze and so on. In general media, it is dominated by uniform corrosion. There is strong stress corrosion susceptibility in the solution in the presence of ammonia, and there are also ...Read more -

What are the factors that cause copper alloy corrosion

Copper alloy corrosion atmospheric corrosion The atmospheric corrosion of metal materials mainly depends on the water vapor in the atmosphere and the water film on the surface of the material. The relative humidity of the atmosphere when the corrosion rate of the metal atmosphere begins to increa...Read more -

Smelting properties of tin bronze

The most harmful impurities in tin bronze are aluminum, silicon and magnesium. When their content exceeds 0.005%, the resulting SiO2, MgO and Al2O3 oxide inclusions will contaminate the melt and reduce the performance of some aspects of the alloy. When smelting tin bronze, since the boiling point...Read more -

Copper alloy composition detection and characteristics

Copper alloy composition detection and characteristics? What are the detection methods of copper alloy composition? Copper alloy composition detection steps? What are the characteristics of copper alloy composition detection? The copper alloy composition we are talking about here mainly refers to...Read more -

The production process of tungsten copper alloy

The production process of tungsten copper alloy: The technical process of preparing tungsten-copper alloy by powder metallurgy method is used for mixing, limiting, forming, sintering, melting, infiltration and cold production of powdered ingredients. Tungsten-copper or molybdenum-copper mixed pow...Read more -

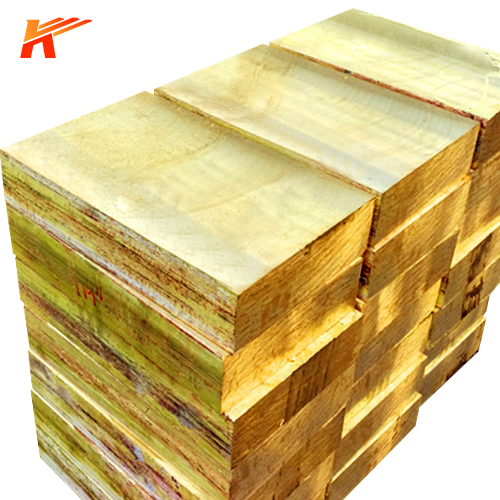

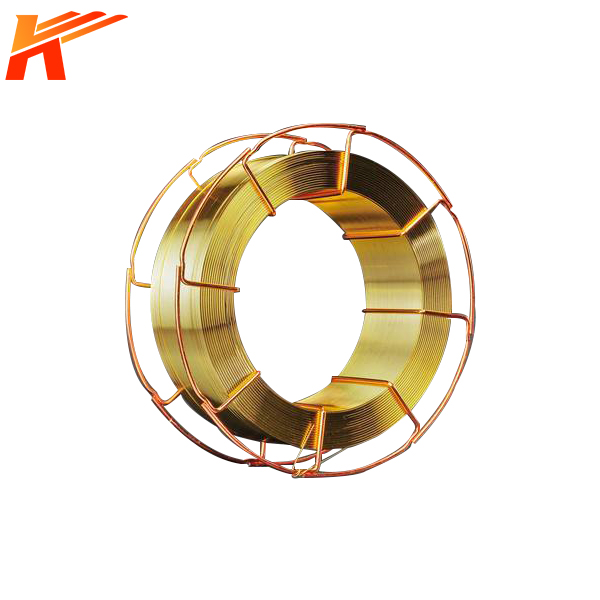

Processing method of copper and copper alloy sheet, strip and foil

Processing method of copper and copper alloy sheet, strip and foil: Rolling is the basic method for the production of copper and copper alloy strips. Rolling is in a gap between two rolls that have a certain pressure on each other and rotate in opposite directions to roll out the product, and the...Read more -

Application of various grades of tin bronze

QSn4-3 tin bronze: tin bronze containing zinc. It has high wear resistance and elasticity, good anti-magnetic properties, can withstand hot or cold pressure processing well; in hard state, good machinability, easy welding and brazing, corrosion resistance in atmosphere, fresh water and sea water ...Read more -

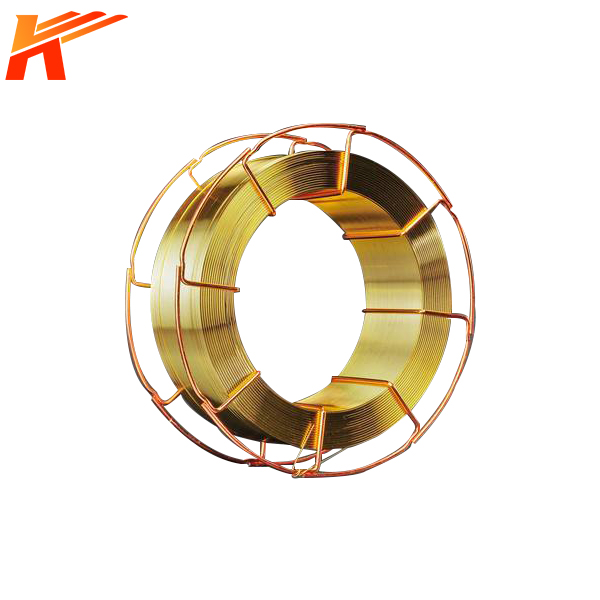

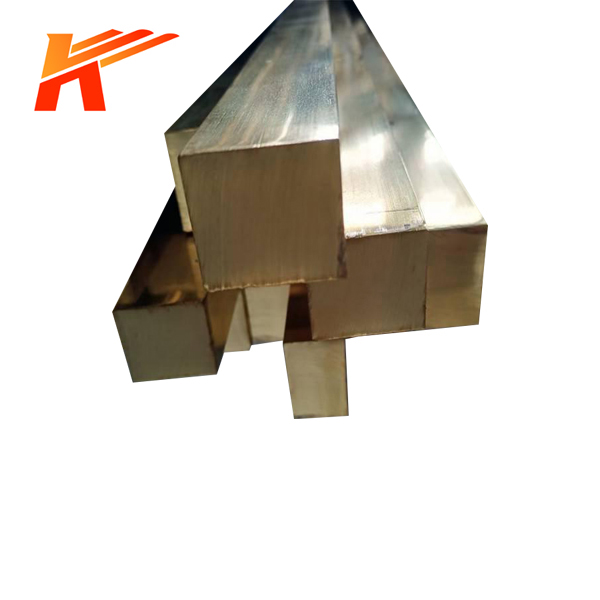

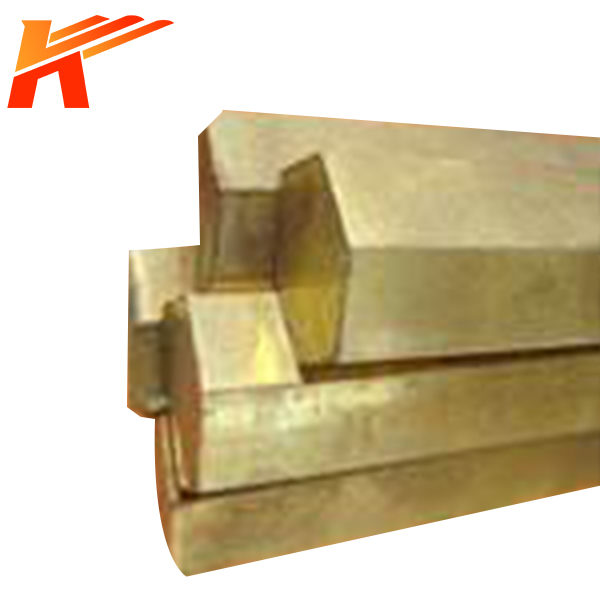

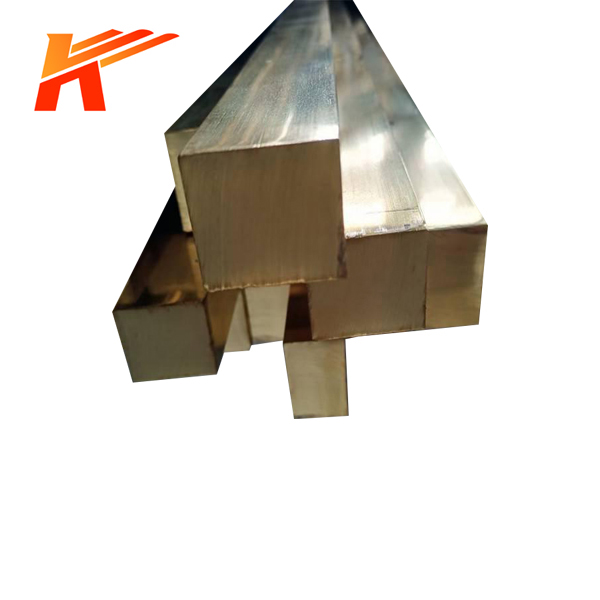

Use of special brass

In order to meet the requirements of making structural parts, it is widely used in the industry to add alloying elements to copper to make copper alloys with enhanced properties. Brass is a copper alloy with zinc as the main alloying element, which has good mechanical properties and is easy to pr...Read more -

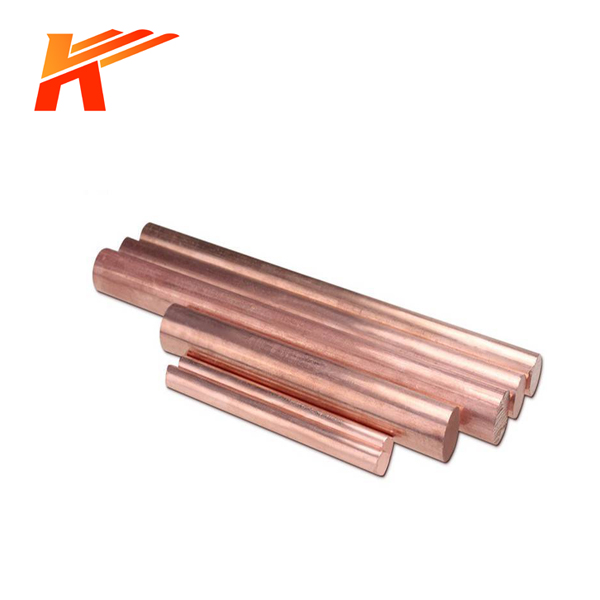

What are the ways to identify pure copper

1. Check the hardness: the higher the fineness of copper jewelry, the softer the texture and the whiter and smoother the surface. Copper alloy manufacturers take copper bracelets of about 60 grams as an example. If they are pulled open by hand, there is no elasticity, and their fineness is about ...Read more