Industry News

-

Effect of Cerium on Properties of Tin Phosphor Bronze Alloy

Experiments have proved the influence of cerium on the microstructure of the tin-phosphor bronze QSn7-0.2 alloy that has been cast, homogenized and recrystallized. The mesh becomes finer, and the grain structure is obviously refined after deformation annealing. Adding a small amount of rare earth...Read more -

What is the density of tin bronze?

Tin bronze density specific gravity ρ (8.82). Bronze can be divided into two categories: tin bronze and special bronze (ie Wuxi bronze). For casting products, add the word “Z” before the code, such as: Qal7 means that the aluminum content is 5%, and the rest is copper. Copper casting ...Read more -

The difference between aluminum bronze and beryllium copper

Beryllium copper, also known as beryllium bronze, is the “king of ductility” in alloy copper. After solid solution aging quenching and tempering treatment, a commodity high toughness forged beryllium bronze aluminum alloy with high toughness and high electrical conductivity can be obt...Read more -

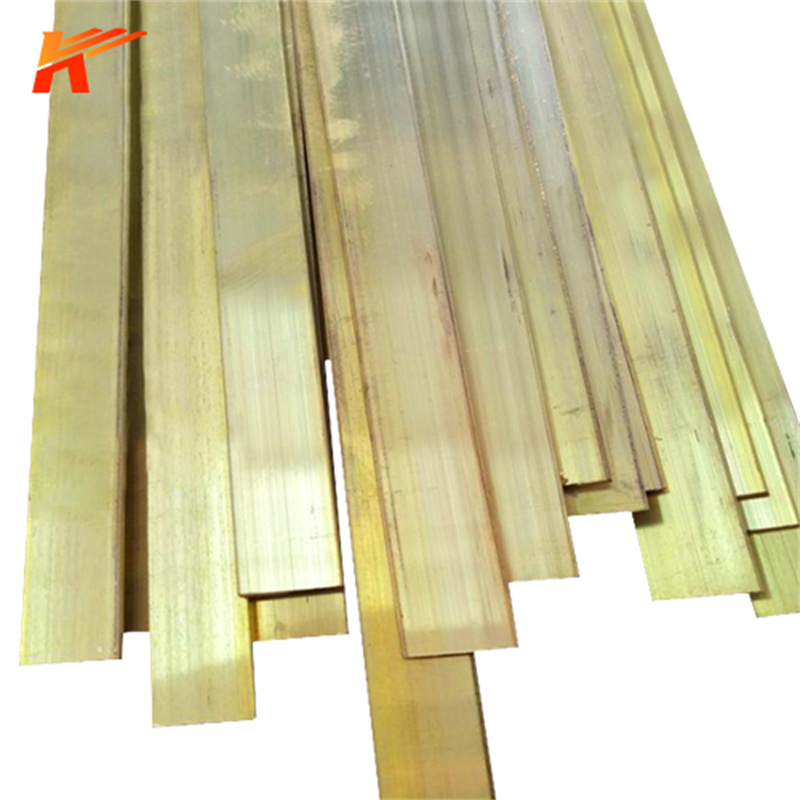

Characteristics of common copper alloys

The most commonly used copper and its alloys are: pure copper, brass, bronze, etc. The appearance of pure copper is red-yellow. In the air, the surface will form a purple-red dense film due to oxidation, so it is also called red copper. The electrical conductivity and thermal conductivity of pure...Read more -

Alloying of copper

Liquid state is an intermediate state between solid state and gaseous state. Solid metals are composed of many grains, gaseous metals are composed of single atoms that resemble elastic spheres, and liquid metals are composed of many groups of atoms. 1. Structural characteristics of liquid metals ...Read more -

Copper smelting technology

At present, the smelting of copper processing products generally adopts induction smelting furnace, and also adopts reverberatory furnace smelting and shaft furnace smelting. Induction furnace smelting is suitable for all kinds of copper and copper alloys. According to the furnace structure, ind...Read more